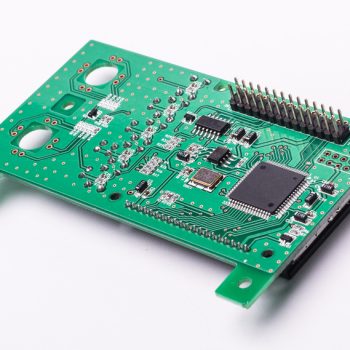

Any circuit board prototyping engineer knows the importance of a coating and finish. In general, the PCB usually has a copper coating and is crucial to the overall efficiency of the board as it protects its components from being exposed to oxygen and other elements. Certain areas on the prototype PCB may also be gold plated for use as contact pads. Only a thin gold plating is required for this, but if for any reason the gold has to be thicker, an electrolytic process is needed.

Interested in learning more about other finishes for prototype circuit boards? Here are some good tips that will help you with your PCB fabrication.

HASL/Lead-Free HASL

This is the most common finish used for PCBs, and the process behind it is pretty straightforward. The engineer immerses the circuit boards into a container filled with melted tin or lead, then once taken out, hot air is blown across the board to remove leftover solder. One of the large advantages of this technique is that it allows the PCB to be exposed to incredibly high temperatures, up to 509 degrees Fahrenheit. Plus, by dipping the entire board in solder, this allows the engineer to notice if there are any problems with the lamination.

Immersion Tin

Immersion Tin is a metallic finish that is deposited directly onto the board, instead of being dipped. The finish is actually a result of a chemical reaction with the board’s copper coating, and this tin will protect the board from additional oxidation down the road.

OSP/Entek

Standing for Organic Solderability Preservative, this water-based organic compound is applied to the exposed copper via a conveyor belt process. It is meant to protect the copper before soldering, and one of its largest benefits is that it is an eco-friendly alternative to other heavy metals.

Electroless Nickel Immersion Gold (ENIG)

This is a two-step process; first, the nickel is coated onto the copper, then topped off with gold. The nickel is what you would actually solder your components to, and the gold is what will protect the nickel during storage and shelf life.

Have any additional questions about the different types of finishes for prototype PCBs? Contact our experts today.