Metal Core PCB (MCPCB) or Insulated Metal Substrate (IMS PCB) is a technology developed to overcome the thermal limitations of the FR4 material. Metal Core is a better choice than FR4 if your boards need to perform in high temperature environment.

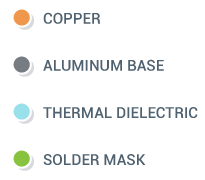

Insulated Metal Substrate provides electrical isolation between the copper and the metal core by using a special dielectric with the peculiarity of having high thermal conductivity.

The most common material used in the substrate is aluminum, for this reason, these type of boards are usually known as Aluminum PCBs.

| ITEM | DESCRIPTION | SYMBOL | STANDARD | ADVANCED |

| No. of Layer Count | Max Layer Count | NA | 1-4 layer | 1-8 layer |

| T-clad Laminate Supplier | Laminate Supplier | NA | Bergquist, polytronics, boyu | Bergquist, polytronics, boyu |

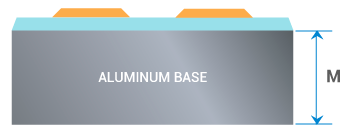

| Metal Thickness | M | 0.4-3.2mm | 0.4-3.2mm | |

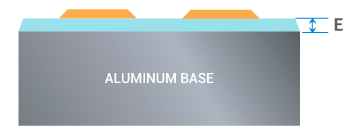

| Dielectric Thickness | E | 100-200um | 100-300um | |

| Thermal Conductivity | NA | 1W/m-k , 2W/m-k 3W/m-k | 1W/m-k , 2W/m-k 3W/m-k , 4W/m-k | |

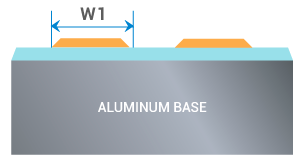

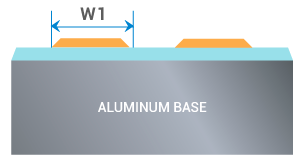

| Circuit Width | Outer Layer Min. Circuit Width | W1 | 0.15mm | 0.15mm |

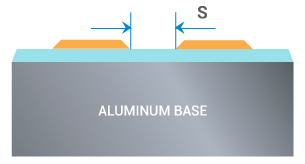

| Circuit Spacing | Outer Layer Min. Circuit Spacing | S | 0.15mm | 0.15mm |

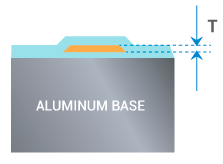

| Copper Foil Thickness | Copper Foil Thickness | T | ½- 4 oz | 1/3 –6 oz |

| Finished Hole | Min. Finished Npth Hole Size | X | 1.0mm | 0.80mm |

| Npth Hole Tol. | A | /-0.05mm | +/-0.05mm | |

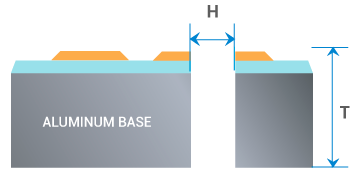

| Max. Aspect Ratio | Max. Aspect Ratio | T:H | 8:1 | 10:1 |

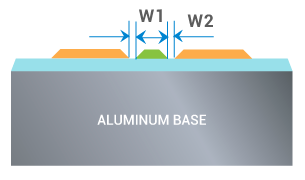

| S/M Dam & Clearance | Min. S/m Dam | W1 | 0.10mm (Green S/M); 0.13mm (white S/M) | 0.10mm (Green S/M); 0.13mm (white S/M) |

| Min. S/m Clearance | W2 | 0.075mm (Green S/M); 0.075mm (white S/M) | 0.05mm (Green S/M); 0.05mm (white S/M) |