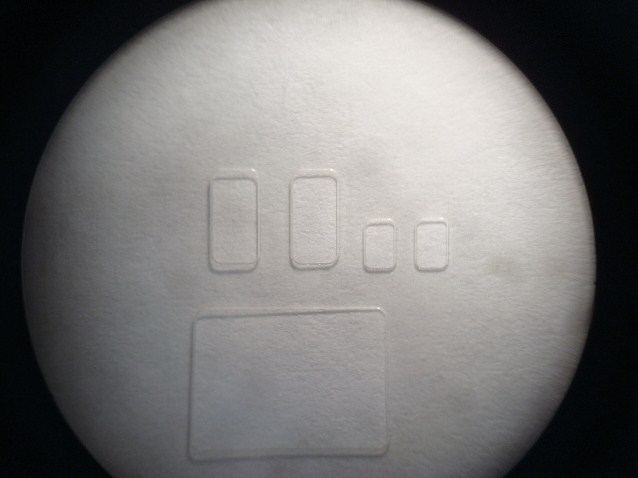

These are low cost SMT Stencils made out of Mylar or Kapton, used mainly by students and hobbyists to assemble prototype printed circuit boards. We use state-of-the-art UV laser technology to produce smooth aperture walls resulting in excellent print performance.

With our UV laser technology we create your custom stencil with a thickness of 0.003" or 0.004", offering the best precision cut you can find in the market..

Pricing: $50.00 for the first 25 square inches, $1.85 for each additional square inch.

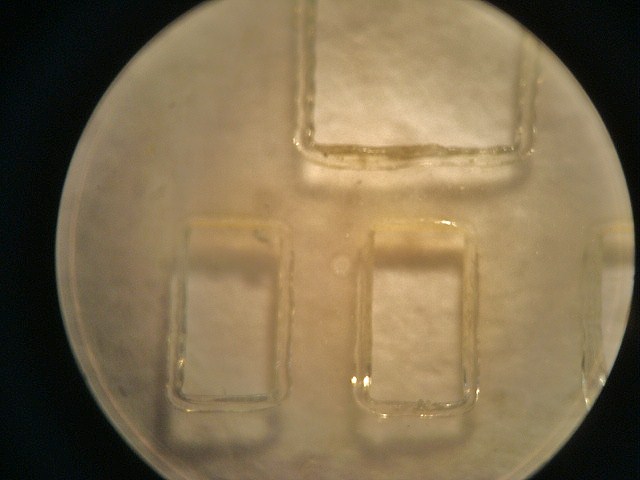

The UV laser has a narrow KERS. It removes material micron by micron for perfectly smooth aperture walls.

The KERS of the CO2 laser is 10 times greater. It cuts through the material. Therefore the aperture walls are not perfectly smooth

Mylar is a polyester film made from stretched polyethylene terephthalate which allows to make great prototype stencils because of its high tensile strength. Kapton is a polyimide film produced from the condensation of pyromellitic dianhydride and oxydiphenylamine, which not only offers higher tensile strength and reliability than Mylar but has the ability to maintain its excellent physical, electrical, and mechanical properties over a wide temperature range.

The main difference between Mylar and Kapton is that Kapton can remain stable in a wide range of temperatures, from -273 to +400 °C (- 459 to + 752 °F)

while Mylar's range is about -70 to +180 ºC (-94 to + 392 ºF), this allows Kapton to be one of the most used materials in flexible printed circuits.

In 2003, Stencils Unlimited introduced the process using Prototype SMT stencils with a Toaster Reflow Oven to assemble prototype PCBs. The same process can be used with Mylar & Kapton SMT stencils. We are backing that with a money-back guarantee program. Buy a low cost Mylar & Kapton SMT stencil and try it using our recommended process. If you are not satisfied with the results, you may return the stencil for a complete refund.

| Mylar/Kapton Stencils | Prototype Stencils | |

| Material | Mylar or Kapton | Stainless Steel |

| Price | $50 | $125 only the foil. $145 with Stencil Kit |

| Lead-Time | 48-Hour Turn | 24-Hour Turn |

| Durability | Short Life (approximately up to 100 applications) | Long Life |

| Precision | Less accurate aperture registration | More accurate aperture registration |

| Users | Students and Hobbyists | Students, Hobbyists and PCB Professionals |

| Technology used to make the stencils | 100% laser cut (using our laser cutting services) |

| Material used | Mylar or Kapton |

| Stencil thickness | 0.003" - 0.004" |

| Maximum size | 10”x10” inches |

| Aperture tolerance | within .00025 inches |

| Allow for Fiducial Data | Yes |