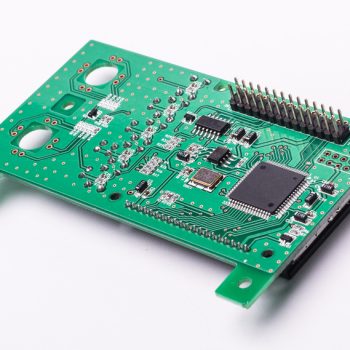

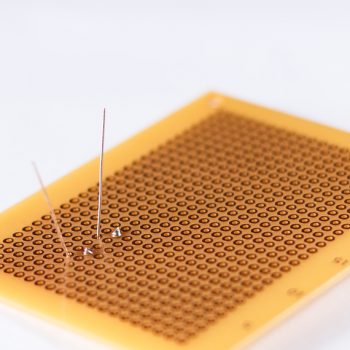

Printed circuit boards, or PCBs, can come in all shapes and sizes due to the variety of electronics that need them. From a thick ¼ inch to a thin .2 mm, the thickness of a PCB can vary greatly depending on the demand. That is why it is important to know how to choose the right thickness for your PCB prototype.

Factors

PCBs have multiple factors that affect their thickness, and each is something important to consider when designing one for your use. The size of the copper is a big thing to consider, as it controls the signal’s strength and reliability and can overheat if made too small. The other materials to make the layers of PCB can also greatly affect the thickness of the board. Also, the number of layers has a large impact on the size of the PCB and the required size of the parts in the PCB.

Why PCB Thickness Matters

There are many things to consider when deciding what the thickness should be on your custom PCB prototypes. Thinner electronics are becoming more popular as time goes on, raising the demand for thinner PCBs. However, this leaves the PCB in a more fragile state and can lead to damaging the electronics. Larger PCBs can usually handle a bit more while being harder to damage but they increase the weight and take up more room in the electronics. You should also consider the cost to produce PCBs of different sizes. Although a PCB can vary in size quite a bit, there is a standard size of about 1.57 mm. This means that when ordering a custom PCB, it can cost more if you do not use the standard thickness, as it requires more work to change the size.

Now that you know how to choose the right thickness for your PCB prototype and can make informed decisions, it is time to start trying your designs. We here at PCB Unlimited are more than capable of helping you build the PCB that you need—no matter the thickness.