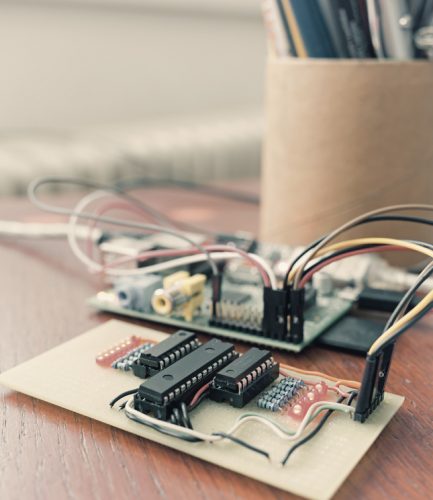

The world of prototype circuit boards can be pretty complex. If you are thinking about getting into the world of printed PCBs, then you should start small. One detail that is important for any engineer to know is the process of SMT stencil printing. Here we explain more.

What is SMT?

Simply put, SMT is the process of placing solder paste on a PCB layout in order to create secure electrical connections. All you will need for this is a stencil, solder, and a printer.

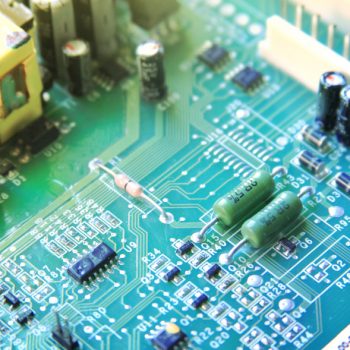

What exactly is solder?

This paste is made of solder metal and flux, which is a chemical cleaning agent. Not only does it act as an adhesive when components are placed on the board, if it is placed properly, the led would be wettened, which creates a strong current via the pad of the board and the component.

Why do I need a printer?

The engineer needs a printer because it is the best way to ensure the solder paste goes exactly where it is needed. The printer’s system will align the board and components, and the solder paste is squeegeed on the board. Typically, this will take between 15-45 seconds for each board, making it a great option for those who need a large number of boards within a tight time frame.

What are the steps for printing prototype printed circuit boards?

The steps are as followed:

1. Design: All PCBs should have reference points marked on them so they will know exactly where the solder needs to be aligned to meet the pads. This part is especially easy on simple, one layered board, which mean they only contain copper tracks on only one of its surfaces.

2. Masking: The space between the pads and the board is often layered with a solder mask to improve the accuracy and to control the flow of the solder.

3. Finish: As one of the last steps, the pads and solder are covered with copper as without this protective coating, the components are prone to oxidation.

SMT stenciling can be quite a complex process, so if you have any questions about this important aspect of prototype printed circuit boards, please contact our professionals today!