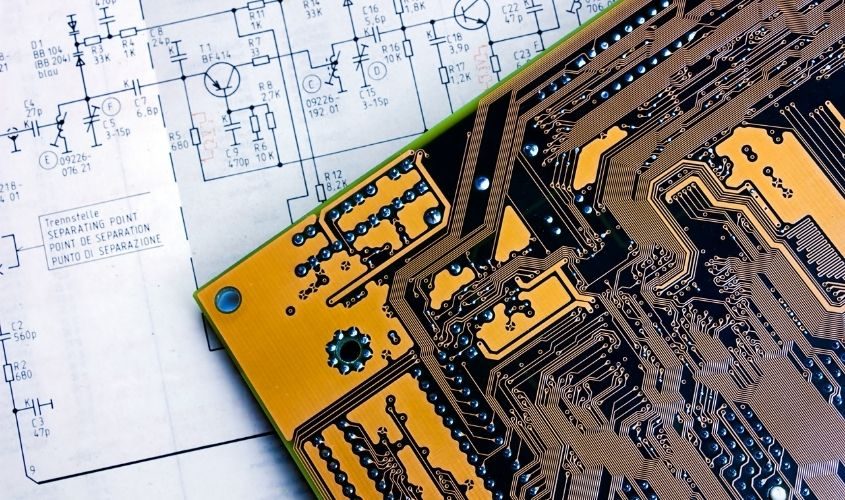

Building a printed circuit board (PCB) is more than coming up with the design and sending it off for production. Proper PCB fabrication should include a prototype stage where you send in your design to create a single PCB you can test. This way you can improve your design before producing a full line. To help you with the prototyping step, here’s everything you need to know about prototype PCBs.

Why You Need To Prototype

A prototype PCB is all about testing your design with minimal investment. If you merely make a design without testing it, you could lose all your invested money from simple errors. A prototype helps you find these flaws and adjust your designs before you commit to full production.

How a Prototype Is Different

A prototype is different from full production in many ways and it’s important you know the differences before you order a prototype.

Smaller Line

Most production companies will only make a few examples of the PCB when you order a prototype—somewhere from 1-100 PCBs that you can test. This means you don’t need to waste a lot of money on simple testing.

Faster Production

Because you only need a few PCBs for prototype runs, the production is usually much faster. It can take only a few business days to create all the prototypes you need for testing. This makes it easy to adjust any design flaws and test your new designs without wasting a lot of time.

Testing Materials

The last big difference between Prototype PCB production and regular production is the materials that make up the PCB. A lot of companies make your prototype PCBs with cheaper materials similar to the design specifications. This keeps the cost down for both you and the production company, but still lets you accurately test if your PCB will work.

After learning everything you need to know about prototype PCBs, you can see how necessary they are to PCB design. You might not need prototypes for small PCB production, but any big PCB line should use prototypes to inform their production process and design choices.