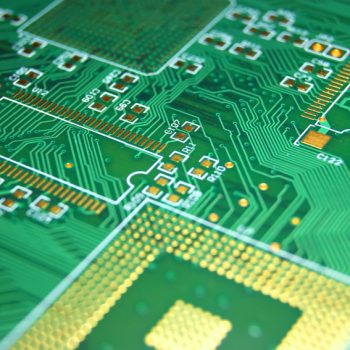

There are plenty of different kinds of circuit boards, but in general, there are three major types of printed PCB fabrication: single-sided, double-sided, and multi-layered. However, no matter the type, one thing is for sure and that is the need for SMT stencils.

In the world of circuit board prototyping, an SMT stencil is needed as a way to transfer solder paste to the PCB layout. The way the stencil works is simple:

- A stainless steel laser is used to cut out openings for each component that will be on the board.

- The stencil is aligned on the board.

- Solder paste is applied all over the stencil, and a squeegee is used to evenly coat all the openings.

- Then the stainless steel foil is removed, leaving the solder paste ready for placement of the components.

Easy enough right? Well besides using SMT stencils to help ensure you have an efficiently working board, there are plenty of other benefits of investing in PCB stencils. Here we explain.

- By using a stencil, you are single-handedly eliminating any human error that comes with prototype PCB assembly by hand. Hand soldering can take a lot of time as it requires precision and patience, while a stencil does it all for you.

- Increase the quality of your completed PCB. You will not have to deal with too much solder paste causing bridging, tombstoning, or balling on the board.

- Decrease your out of pocket expenses as SMT stencils are much cheaper than production stencils.

- Boost the effectiveness of your PCB layout. Meaning you are able to design a well thought out board without having to worry about having to place solder in tiny spaces by hand.

With all of these advantages in mind, it is clear that using SMT stencils in your prototype PCB fabrication will only boost your efforts. You will be able to save time, money, and prevent any and all headaches from happening as the PCB assembly will go by like a breeze.

Have any additional questions about using SMT stencils within your prototype printed circuit boards? Contact our professionals today.