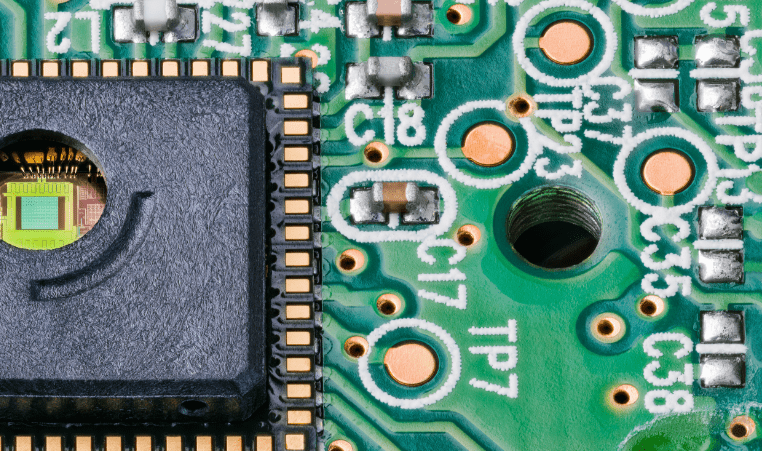

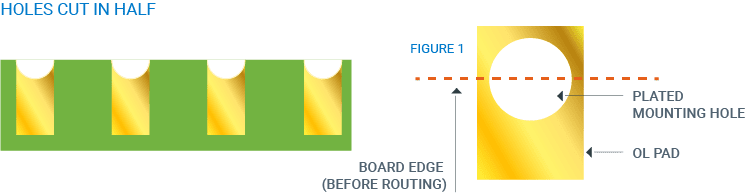

Castellated mounting holes, also known as castellations, are plated through holes located at the edges of a printed circuit board that are cut through using a PCB router to form half-plated holes. These castellated holes usually have a half-circular shape, but they can have other shapes, depending on the application.

Design of Castellated Holes

Hole Shape, Size and Spacing: Castellated mounting holes typically have a round shape, but they can also be square or rectangular. The size of the holes should accommodate the screws or other fasteners being used for mounting. Spacing between the holes should be sufficient to prevent solder bridging and ensure proper electrical isolation between connections.

Castellation Depth and Width: The depth and width of the castellations depend on the thickness of the material being mounted and the size of the solder joint required. The castellations should be deep enough to ensure a strong solder joint but not so deep that they weaken the structural integrity of the mounting hole.

Spacing and Alignment: Ensure proper spacing and alignment between the castellations to facilitate soldering and assembly. The castellations should be evenly spaced around the perimeter of the mounting hole to provide uniform support.

Thermal and Mechanical Factors: Depending on the application, you may need to consider thermal and mechanical factors. For applications subjected to high temperatures or mechanical stress, may need to use thicker material, or increase the size of the castellations to ensure proper stability and reliability.

Benefits of Castellated Mounting Holes

Space-saving – Castellated holes eliminate the need for additional connectors or headers, allowing for more compact printed circuit board designs.

Simplified Assembly – Castellated mounting holes simplify the assembly process, reduce assembly time and labor costs by providing an easy way for soldering components directly onto another surface, such as a larger printed circuit board or another module.

Increase Stability and Reliability – Castellated mounting holes, with notches or gaps around the perimeter, provide strong mechanical connections between components. This guarantees stability and reliability in applications subjected to vibration or mechanical stress.

Improved Electrical Connection – Castellated holes provide robust electrical connection between components thus minimizing signal loss and ensuring consistent electrical performance.

Modular Design – Castellated mounting holes enable a modular design approach, which enhances flexibility, scalability, and ease of upgrades or repairs.

Lower Assembly Cost – By eliminating the need for additional connectors or mounting hardware between components.

Disadvantages of Castellated Mounting Holes

Complexity in PCB Design: Integrating castellated mounting holes into a printed circuit board design can add complexity. Proper placement and sizing of the holes are critical to ensure alignment and compatibility with other components.

Increase Manufacturing Costs: Fabricating printed circuit boards with castellated mounting holes require specialized equipment and technique to ensure precise cutting and plating of the holes.

Increase Risk of Solder Bridges: The design of castellated mounting holes may increase the risk of solder bridges forming between adjacent pads during the soldering process.

Limited Reusability: Once components are soldered onto a surface using castellated mounting holes, they may be difficult to remove or reuse without causing damage to the printed circuit board or the components themselves.

Assembly Complexity: While castellated mounting holes can introduce additional complexity, particularly in hand soldering operations or when working with automated assembly equipment.

Interference with Signal Traces: The presence of castellated mounting holes on a printed circuit board may interfere with nearby signal traces. Designers need to carefully consider the placement of these holes to avoid signal integrity issues.

Despite these disadvantages, castellated mounting holes remain a valuable option in many electronic hardware designs.

Applications of Castellated Mounting Holes

Castellated mounting holes offer versatility, reliability, and space-saving benefits, making them suitable for a wide range of applications such as:

Wireless Communication Modules: Castellated mounting holes are often used in radio frequency (RF) modules, such as Wi-Fi modules, Bluetooth modules, and RF transceivers.

Internet of Things (IoT) Devices: Castellated mounting holes facilitate the integration of multiple components, sensors, and communication modules onto a single printed circuit board, enabling compact and robust designs.

Embedded Systems: In embedded systems, where space is limited, castellated mounting holes are used to attach small modules to the main PCB.

Wearable Technology: Wearable devices benefit from the space-saving nature of castellated mounting holes.

Industrial Control Systems: Castellated mounting holes are used in devices like industrial controllers, data acquisition systems, and automation equipment. They provide secure connections and withstand harsh environmental conditions.

Consumer Electronics: Consumer electronic devices, such as gaming consoles, media players, and smart home devices, use castellated mounting holes for integrating additional features or expanding functionality.

Future Evolution

The future of castellated mounting holes in electronic hardware design is likely to be influenced by several factors:

• Miniaturization Trends

• Advanced Manufacturing Techniques

• Integration with Emerging Technologies

• Innovations in Assembly Processes

• Material Advancements

PCB Unlimited offers PCB fabrication services and PCB assembly services. You can get an online quote for USA Quickturn PCBs, Taiwan PCBs and China PCBs, request a custom quote by simply email your design files to support@pcbunlimited.com.