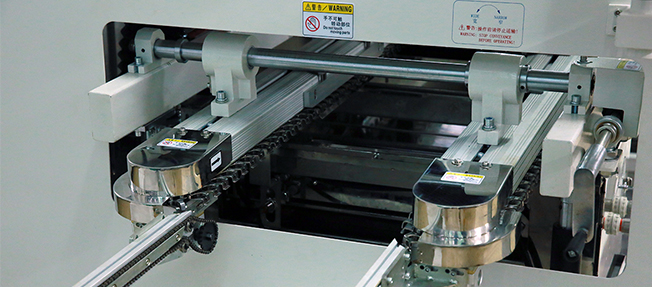

High quality heavy double hook titanium finger ,V and L type is optional

High-precision, automatic spray fluxing system

Spraying evenly and customized flux recovery system

Standard with 3 hot air bottom preheating zones

Standard with simple center support system on solder pot, it is possible to adjust the position of the support point

Top and bottom cooling system after soldering

The Flux Spraying System is perpendicular to the PCB, so it spread more even on PCB and Enhance flux penetrating property to the holes improving the adhesiveness of the solder metal Effectively reduce operating cost.

10mm thickness casting iron solder pot, no easy to deform when heating, perfect contact with heater for more uniform heating, used graphite for insulation for anti-moisture and anti-corrosion The pot is ceramic, coating for a smoother surface, prevent corrosion, longer life time.

Standard equipped with strong conveyor finger, hardly get bent. Good for both bare PCB and also 5kg weight carrier. Specially designed for heavy load carrier.

Industrial PC and Siemens PLC for controlling system, English interface. Can stock numerous groups parameters. Direct input target temperature into the program Display actual temperature.

| Model | HW350 | HW450 | HW610 |

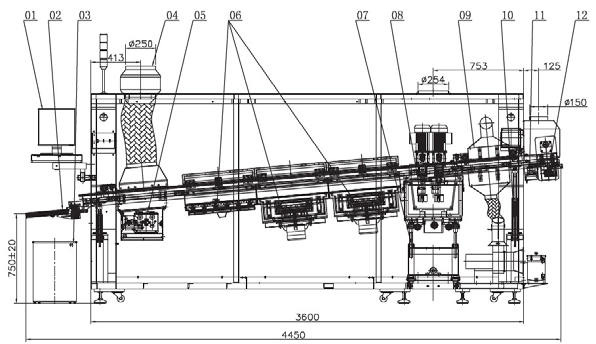

| Dimensions LxWxH(mm) | 4450x1400x1700 | 4450x1500x1700 | 4450x1670x1700 |

| Weight | Approx. 1800kg | Approx. 2100kg | Approx. 2600kg |

| Power Supply | 3PH 380V 50HZ | 3PH 380V 50HZ | 3PH 380V 50HZ |

| Startup Power | 32KW | 32KW | 45KW |

| Operation Power Cons | Approx. 8KW | Approx. 8KW | Approx. 11KW |

| Control System | PC+PLC | PC+PLC | PC+PLC |

| Spraying Movement | (step motor) | (step motor) | (step motor) |

| Spray Pressure | 0.2 Mpa - 0.4Mpa | 0.2 Mpa - 0.4Mpa | 0.2 Mpa - 0.4Mpa |

| Flux Flow Arranga | Option | Option | Option |

| Auto Fill Flux | Standars | Standars | Standars |

| Exhaust | Top Exhaust Side Exhaust | Top Exhaust Side Exhaust | Top Exhaust Side Exhaust |

| Exhaust Ducting d (mm) | Ø 250 | Ø 250 | Ø 250 |

| Exhaust Capacity | 30M°/min | 30M°/min | 30M°/min |

| Preheating Mode | Convection/ IR emitter | Convection/ IR emitter | Convection/ IR emitter |

| Control Mode | PID | PID | PID |

| Preheating Zone Number | 3 | 3 | 3 |

| Preheating Lenght (mm) | 1800 | 1800 | 1800 |

| Preaheating Temperature | Room temp. -200°C | Room temp. -200°C | Room temp. -200°C |

| Warm-up Time (min) | Approx. 12min (settings: 150°C) | Approx. 12min (settings: 150°C) | Approx. 12min (settings: 150°C) |

| Blower Motor | 250W 3PH 220 VAC | 250W 3PH 220 VAC | 250W 3PH 220 VAC |

| PCB Width (mm) | 50-350 | 50-450 | 50-610 |

| Conveyor Direction | L͢R (option: R͢L) | L͢R (option: R͢L) | L͢R (option: R͢L) |

| Conveyor Speed (mm/min) | 500-1800 | 500-1800 | 500-1800 |

| Conveyor Height (mm) | 750±20 | 750±20 | 750±20 |

| Available Comp. H(mm) | Top 120 /Opt: 250) Bottom 15 | Top 120 /Opt: 250) Bottom 15 | Top 120 /Opt: 250) Bottom 15 |

| Conveyor Speed Control Mode | Closed Loop | Closed Loop | Closed Loop |

| Fingers | New design Double-hook Type Finger: 2D-40 | Spring Pressing Double-hook Finger | New design Double-hook Type Option |

| Conveyor Angle | 4-7° | 4-7° | 4-7° |

| Type of Solder Pot | Motor Drive | Motor Drive | Motor Drive |

| Solder Pot Material | Casting Iron | Casting Iron | Casting Iron |

| Wave Height Adjustment | (Inverter) Approx: (Digital Control by PC) | ||

| Cooling Method | (Air Cooling ) Option: (Water cooling) | ||

| Heater Power | 220 V 13.5KW | 220 V 13.5KW | 380 V 18KW |

| Solder Pot Temperature | 300°C | 300°C | 300°C |

| Solder Pot Capacity | 500kg | 500kg | 650kg |

| Wave Drive Power | 180Wx2 3PH 220 VAC | 180Wx2 3PH 220 VAC | 180Wx2 3PH 220 VAC |

| Solder For Warm-up Time | Approx: 150min (setting 250°C) | Approx: 150min (setting 250°C) | Approx: 150min (setting 250°C) |

| Temp. Control Mode | PID | PID | PID |

| Finger Cleaning System | Brush | Brush | Brush |