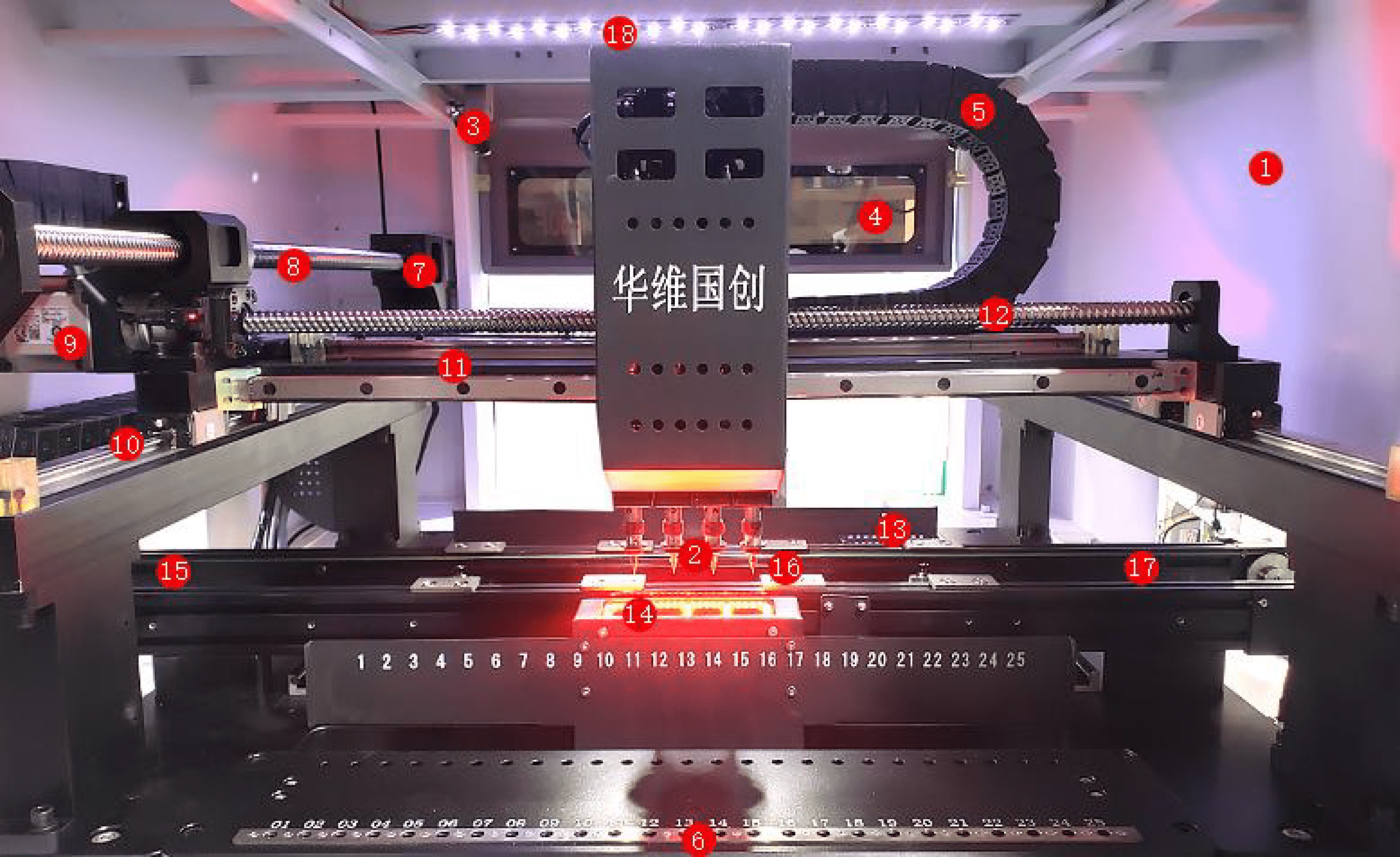

1. Housing

2. Placement Heads

3. Pneumatic Support Bar

4. Safety shield

5. Flexible Silent Cable Carrier

6. Feeder Slots

7. Y Axis Servo Motor

8. Y Axis Ground Ball Screw

9. X Axis Servo Motor

10. Y Axis Linear Motion Guide

11. X Axis Linear Motion Guide

12. X Axis Ground Ball Screw

13. 5MP HD Camera

14. 1MP Fast HD Camera

15. Waiting Area

16. Mounting Area

17. Exit Area

| PARAMETER | SPECIFICATION |

| Model | HW-DU400-64FX |

| Number of Placement Heads | 4 (high-accuracy) |

| Number of IC Trays | 4 |

| Number of Feeders | 64 (subject to 8mm feeder) |

| Positioning Accuracy | 0.01mm |

| Repeatability | 0.02mm |

| Mounting Speed | 12,000 Components per Hour |

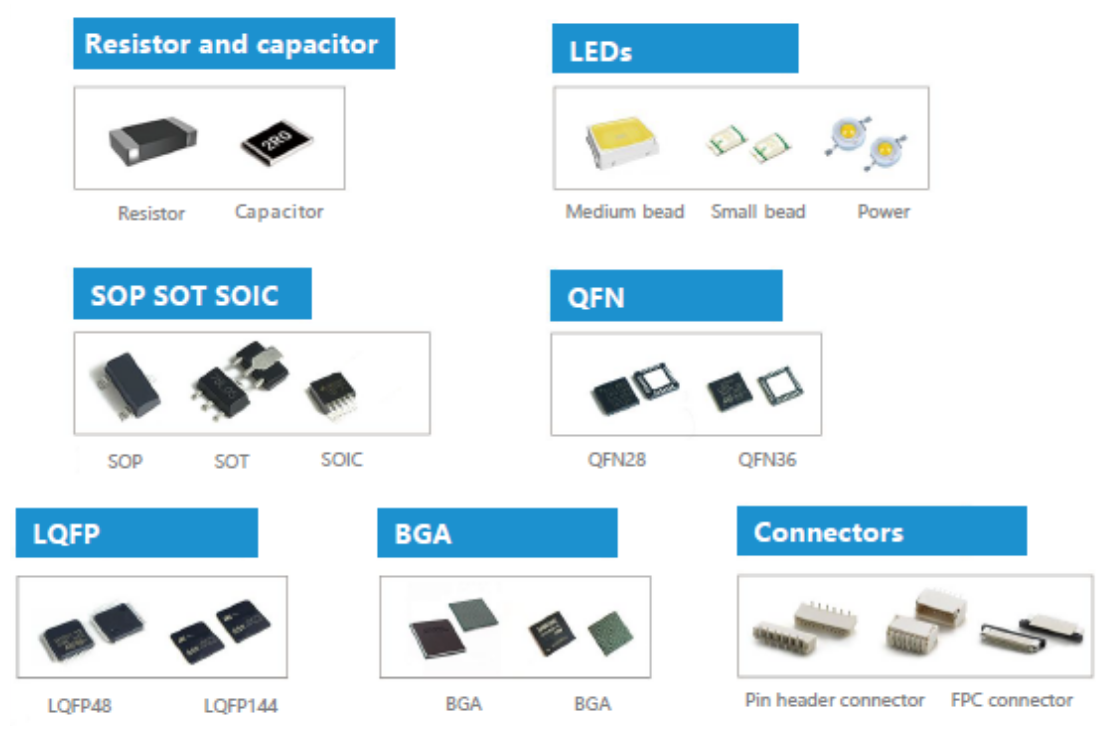

| Component Types | Resistors, Capacitors, Inductors, ICs, LEDs, Connectors, etc. |

| Maximum PCB Size | 510*450mm |

| Feeders | Electric feeder, pneumatic feeder, vibration feeder, IC tray etc. |

| Cameras | Fiducial Camera x1; High Speed 1 MP Camera x4; High Resolution 5MP Camera x1 |

| Maximum Component Height | 20mm |

| PCB Conveyor Transport | Three stage, automatic transport from left to right, automatic PCB positioning |

| Fiducial Recognition | Manual / Automatic |

| Programming Method | Automatic programming after manually importing PCB coordinate files. |

| Control System | Huawei Guochuang control system |

| Maximum XY Axis Travel | 629mm*679mm |

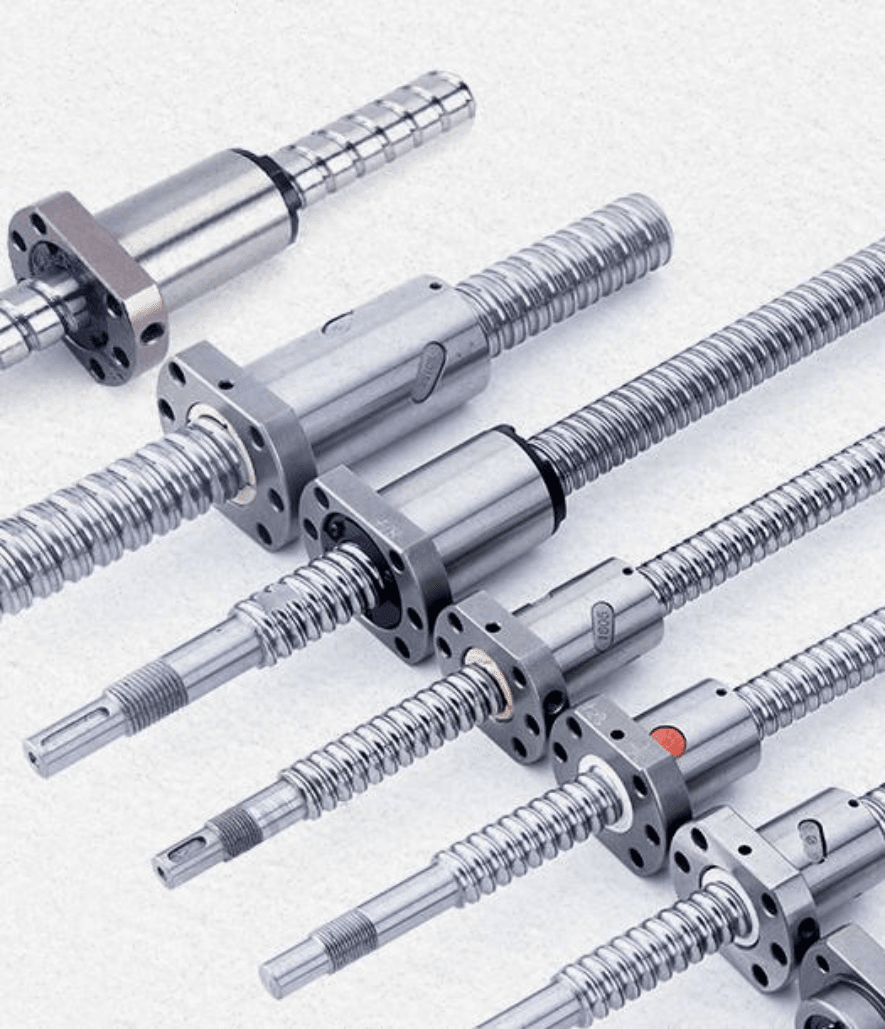

| Motion System | Double linear motion guide + double ground ball screw |

| Motion Control | Sophisticated motion algorithms including advanced acceleration profiles |

| Control Computer | Industrial control computer with Intel high-performance processor |

| Conveyor Track Adjustment | Electric |

| Power Supply | 220V AC, 50Hz |

| Power Consumption | 1.5KW |

| Air Supply | 0.5MPa |

| Dimensions | 1,200mm*1,200mm*1,500mm |

| Weight | 580kg |

17-inch display, keyboard and mouse.

User friendly OS preinstalled.

Currently Windows 10; Windows 11 support available in future update.

Easy to understand software that supports vision programming,

file importing and data preparation.

Imported precision ball srews and linear motion guides ensure long term, maintenance free operation, high

accurancy, low running noise and superior machine performance.

High accuracy allows precision mounting of 0201, 0402, QFN, LQFP, BGA and other package types.

High quality motion system allows continuous operation with minimum downtime, resulting in improved

productivity.

Cable carrier is rated for 10 million cycles.

Igus flexible cables endure extreme temperatures and resist torsional flex problems.

These high quality cables ensure reliable connections during

repeated high speed motion profiles.

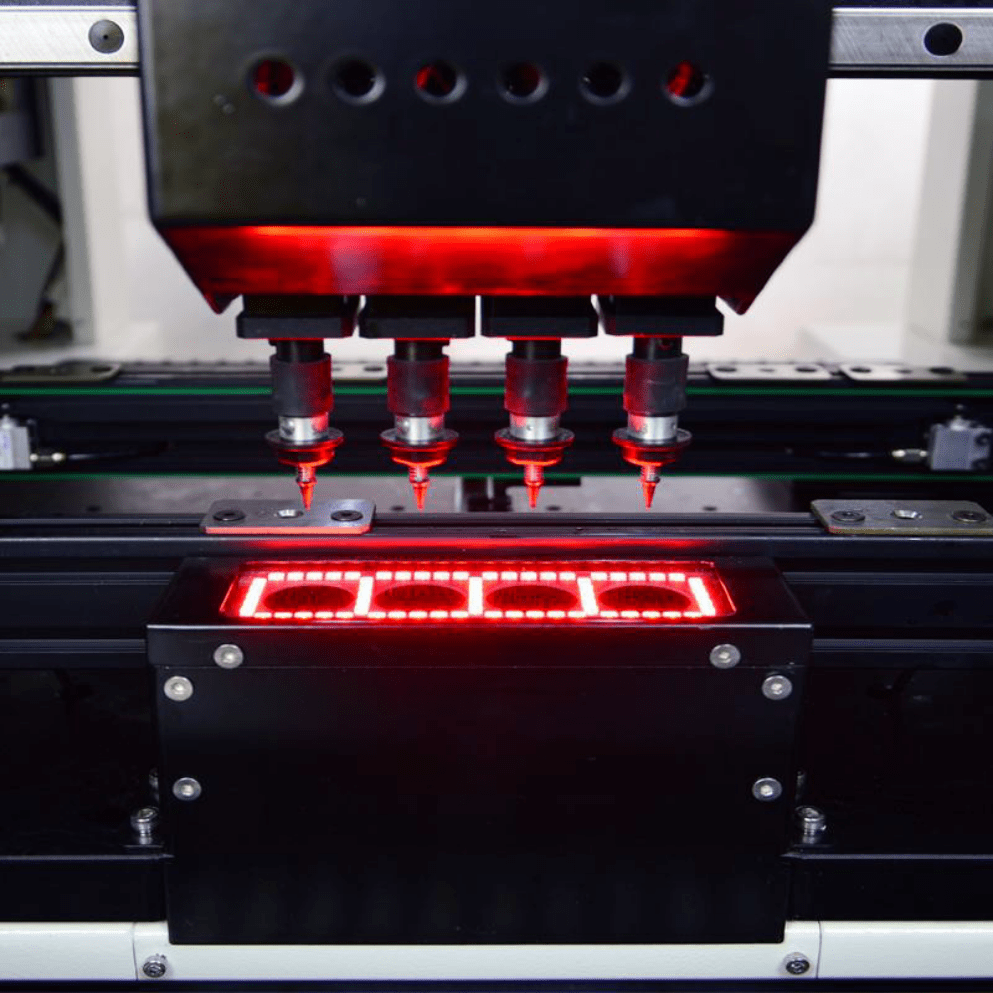

A 5MP distortion free camera is used for mounting chips and other large components.

Four high speed 1MP cameras are used to ensure proper.

placement of smaller components.

Fiducial recognition camera is mounted on placement head.

You can reliably place components as small as 0201.

In addition, you can place 0402, 0603, 0805, 1206, etc.

Place SOT, SOP, TSOP, LPFQ, QFN, etc.

Place BGAs with lead pitch > 0.3 mm pitch.

BGAs must be smaller than 40*40 mm.