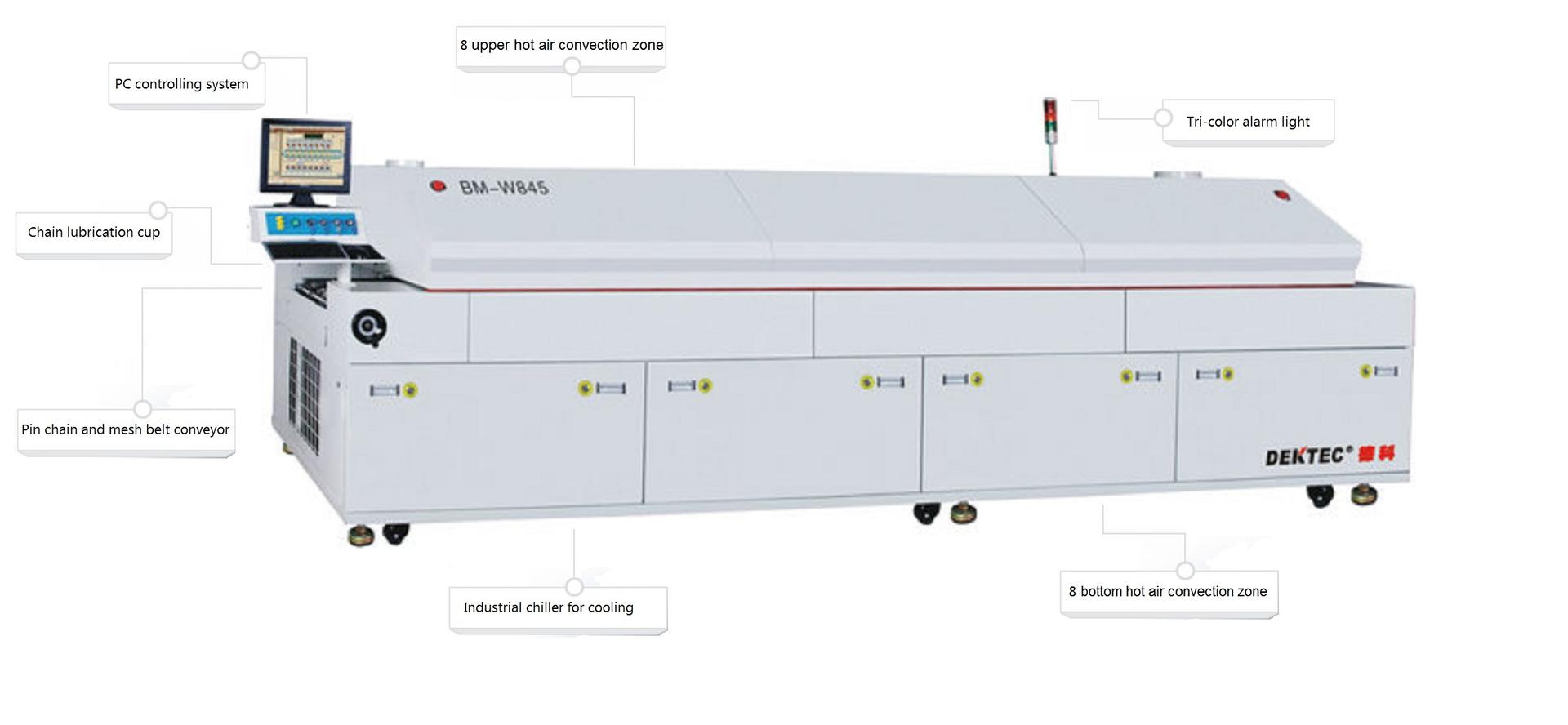

Touchscreen controlled lead-free reflow oven with 8 up and 8 bottom full hot air convection. Built-in chiller cooling zone and pin-chain/mesh belt conveyor ideal for inline production

This convection reflow oven is ideal for mid-to-high volume lead-free soldering production lines.

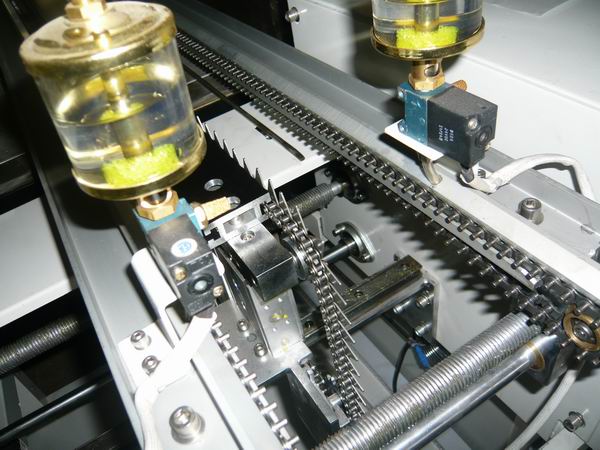

Chain and mesh belt conveyor can accept boards up to 400m (16") and handle speeds up to 1200 mm/min (47"/min). All rail has been harden-treated and comes with lubrication cup

With 8 upper and 8 bottom forced hot air heating zones get full profile control. Ideal for mid to high production.

The built-in chiller provides powerful cold wind to the cooling system, helping you control the cooling of lead-free solders.

The touchscreen interface allows you to save more than 50 groups of parameters including temperatures, speed and alarm. It also comes with 2 extra thermocouple ports for profiling.

| Heating Zones | Upper 8 hot air zones

Bottom 8 hot air zones |

| Heating Method | Fully forced air convection |

| N2 Available | Optional |

| Lead Free | Yes |

| Conveyor Type | Stainless steel mesh belt and Pin Chain conveyor |

| Snema Connection | Yes |

| Component Max. Height | 30mm (1.2") upper, 25mm (1")lower |

| Pcb Width | 400mm (16") |

| Mesh Belt Width | 450mm (17.5") |

| Conveyor Height | 900mm ± 20mm (35" ± 1") |

| Conveyor Speed | 100mm - 1200mm (4" - 47"/min) |

| Center Board Support System | Optional |

| Dual Rail Conveyor System | Optional |

| Heated Tunnel Length | 2.6m (8.75ft) |

| Temperature Accuracy | ±1 °C |

| Delta T | ±2 °C |

| Pid | Yes |

| Ramp Time From Room Temperature to 260 Deg C | < 15 mins |

| Flux Management | Optional |

| Number of Cooling Zones | 2 |

| Cooling Method | Industrial chiller |

| Control | Touch screen + PLC |

| On Board Profiling | Yes |

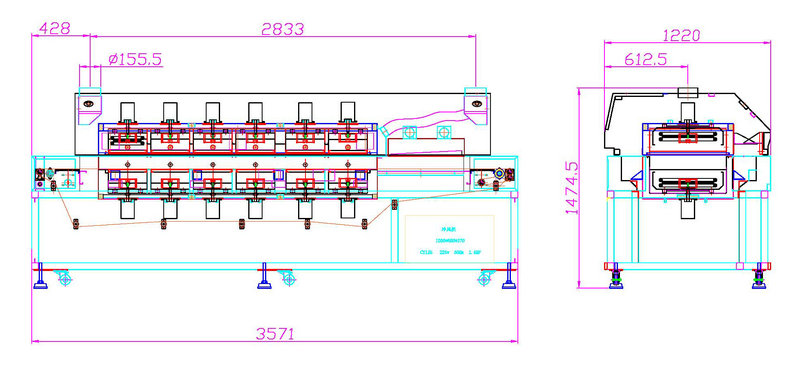

| Dimensions | L4.6mxW1.2mxH1.45m (L15ftxW3.9ftxH4.75ft) |

| Weight | 1300Kg (2866Lbs) |

| Power | 53Kw |

| Exhausting Flow Per Port | 500cmb/hour |

| Number of Exhausting Port | 2 |

| Ups System | Optional |

| Hood Opening | Electrical screw pole |

| Package | Vacuuming package and crate |

| Free Spare Parts | Yes |