Automatic wave solder system with proven performance, self-contained fluxing, preheating and laminar (smooth) solder wave modules. Decrease labor costs by significantly reducing hand soldering.

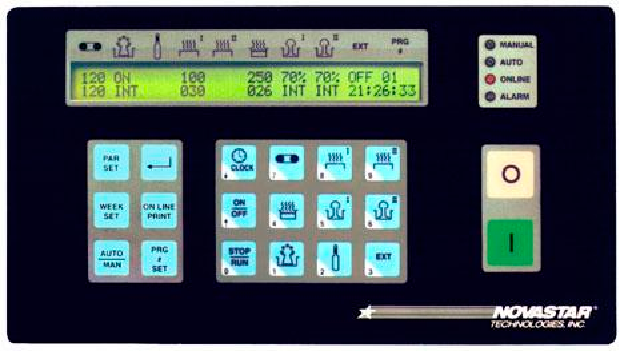

The Spartan 8S (Single wave) and 8D (dual wave) solder machines can process printed circuit board assemblies up to 8” x 11.4” wide and require very little solder for their size. The single or dual wave systems come complete with Conveyor, Foam Fluxer with Integral Air Compressor, Preheaters, and Stainless Steel Solder Pot with drain valve, and compact microprocessor Controller, automatic Wave Soldering Systems.

| Power | 220 VAC, 60 Hz

1Ø, 30A |

220 VAC, 60 Hz

1Ø, 40A |

| Foam Fluxer Tank | 0.5 gal/2 ltrs | 0.5 gal/2 ltrs |

| Solder Pot Capacity | 125 lbs/57 kgs | 300 lbs/136 kgs |

| Max Wave Height | 0-3/8”/0-10mm | 0-3/8”/0-10mm |

| Wave Width | 8.0”/203mm | 8.0”/203mm |

| Max Preheat 1 Temp | 338°F/170°C | 338°F/170°C |

| Max Preheat 2 Temp | 428°F/220°C | 428°F/220°C |

| Preheat 1 Power | 2.25 kW | 2.25 kW |

| Preheat 2 Power | 1.5 kW | 1.5 kW |

| Max Solder Pot Temp | 575°F/300°C | 575°F/300°C |

| Lead Free Pot Temp | 662°F/350°C | 662°F/350°C |

| Solder Pot Power | 2.5 kW | 3.2 kW |

| Approx.Warm-Up Time | 40 min. | 40 min. |

| Max Conveyor Speed | 6 ft/min

(2 m/min.) |

6 ft/min

(2 m/min.) |

| Pallets | STD: 8” x 11.4”

200 x 290 mm |

STD: 8” x 11.4”

200 x 290 mm |

| Overall L. (in/mm) | 96.5/2451 | 96.5/2451 |

| Footprint Length | 66.5/1690 | 66.5/1690 |

| Width (in/mm) | 31/787.4 | 31/787.4 |

| Height (in/mm) | 20/508.0 | 20/508.0 |

| Venting Requirement | 300 CFM/500 m3/h max., 4”/100 mm Dia. Flange | |