Touchscreen controlled lead-free oven with 4 up and 4 bottom full hot air convection zones. Perfect for inline production

This convection reflow oven is ideal for low-volume lead-free soldering production lines.

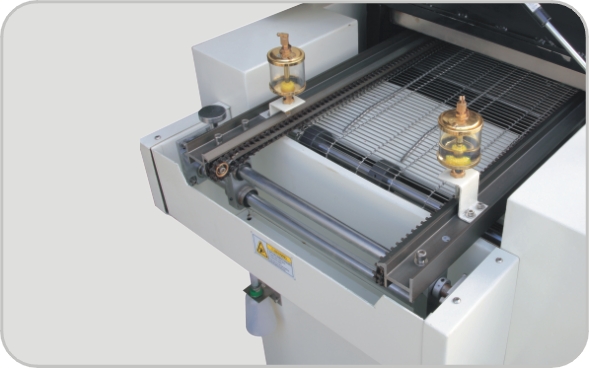

Chain and mesh belt conveyor can accept boards up to 300m (11") and handle speeds up to 900 mm/min (35"/min). All rail has been harden-treated and comes with lubrication cup

With 4 upper and 4 bottom forced hot air heating zones get full profile control. Ideal for prototyping, short-run or low production.

The touchscreen interface allows you to save more than 50 groups of parameters including temperatures, speed and alarm. It also comes with 2 extra thermocouple ports for profiling.

Built with brand electrical components like Schneider (German) breaker, Omron (Japan) box relay and a powerful CE certificated blower, this oven is specially designed for lead-free reflow processes. Performing very stable runs and keeping noise lower than any other of its type.

| Heating zones | Upper 4 hot air zones

Bottom 4 hot air zones |

| Heated Tunnel Length | 38in (980mm) |

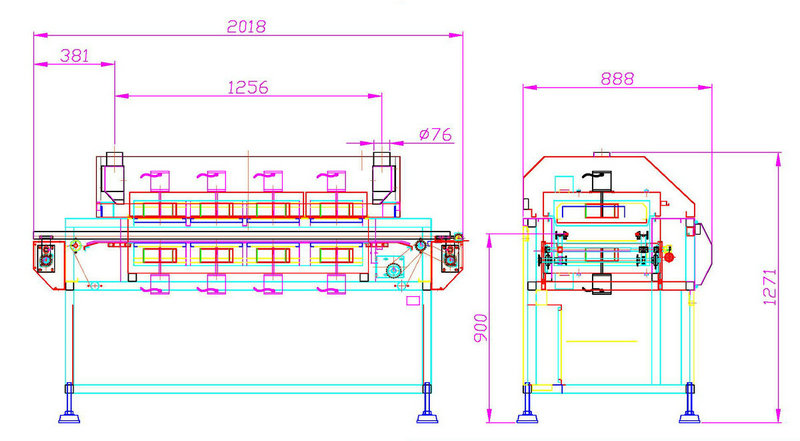

| Dimensions | L8.3ftxW2.5ftxH4ft (L2550mmxW750mmxH1250mm) |

| Net Weight | 620 Lbs (280Kg) |

| Power | 23KW |

| Consumption Power | Aprox. 7KW |

| Ramp Time | 18 minutes |

| Control Type | Micro-processor control |

| Heat Type | Upper/botton zones fully forced hot air convection |

| Temperature Control | PID close-loop. SSR drive |

| Temperature Range | Ambinent-350°C |

| Temperature Accuracy | ±1°C |

| Delta T | ±2°C |

| Cooling Method | Fans |

| Conveyor Type | Stainless steel mesh belt and Pin Chain conveyor |

| Conveyor Height | 35.43±0.79in (900±20mm) |

| Mesh Belt Width | 12.99in (330mm) |

| Max. PCB | 11.81in (300mm) |

| Conveyor Speed | 0-35.43in/min (900mm/min) |

| Conveyor Direction | left to right |

| Hood Lift | Manual with help of plenum cylinder |

| Power Supply | 380v,3ph,50hz (Option: 220v, 3ph,60Hz or 220v,1ph,60hz) |

| Package | Vacuuming |