CALL US

(800) 348-9250

EMAIL US AT

support@pcbunlimited.com

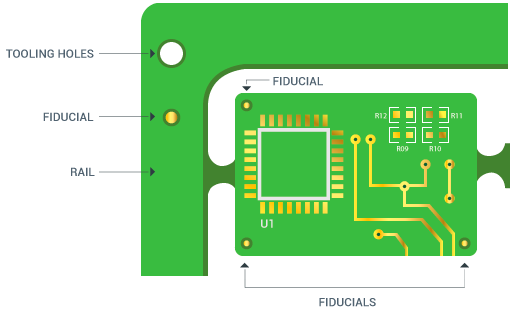

Fiducials are small pads that are placed on a PCB to aid Pick & Place machines during component placement. They are also frequently added to the rails of a PCB array. To achieve better assembly results, we recommend that you always add fiducials to your PCB design.

We recommend that you place one fiducial in each of 3 corners of your PCB design. While only two fiducials are needed, 3 can help ensure that a Circuit Board is not loaded incorrectly into the pick and place machine.

The fiducial locations should also be added to your Pick and Place data file. When an operator loads your PCB, the pick and place machine will find your fiducials and use image recognition to determine their exact location. This helps the machine to orient your PCB; even if it is not placed exactly in the same place each time.

When adding fiducials, keep the following in mind:

1. Fiducials should be inserted in the top and/or bottom copper layers, and they should not be covered by solder mask: The Vision system needs to find the fiducials, and covering them with solder mask will make this more difficult to achieve.

2. Appropriate fiducial shapes are: round, square or diamond. Most fiducials are round.

3. A proper size for a fiducial diameter is about 0.050" (1.3 mm).

4. Fiducials should not have copper nearby, since this could cause the camera from the Vision system to not recognize your fiducial marks.

5. In order to have better results when the triangulation is being performed, fiducials should be placed as far apart from one another as practical.