CALL US

(800) 348-9250

EMAIL US AT

support@pcbunlimited.com

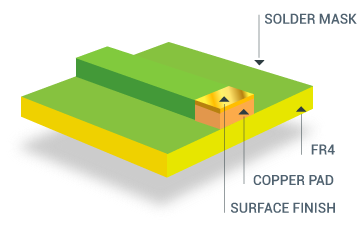

A printed circuit board needs to have a surface finish or coating to protect the copper circuitry from oxidation. The surface finish is also used to provide a solderable surface when assembling to promote reliable solder joints for long-term performance.

HASL (leaded and lead free) has been the most commonly used PCB surface finish in the United States for many years. During the HASL process the printed circuit boards are completely submerged in a bath of molten solder. The excess solder is later removed by blowing hot air across the surfaces of the boards. HASL leaves uneven surfaces and is not suitable for fine pitch or if your boards require small via holes.

OSP is a low cost water-based organic surface finish used since the 70’s. A very thin layer can protect the copper surface from oxidation. OSP is environmentally friendly and provides a coplanar surface however, it has a relative low shelf live.

ENIG is considered the best lead-free finish for fine pitch (especially BGAs) because of its flat surface, good solderability and good shelf live (12 months). It consists of two layer metallic coatings. The nickel layer serves as a barrier to the copper and is the surface to which components are soldered. The gold layer protects the nickel during storage. ENIG can be brittle and is not recommended for applications where shock or strong vibrations.

| CHARACTERISTIC/APPLICATIONS | HASL | OPS | ENIG |

|---|---|---|---|

| Manufacturing costs | Low | Low | High |

| Environmental Hazard | Yes | No | No |

| Thermal Stress | Yes | No | No |

| Surface Finish Durability | Robust | Fragile | Robust |

| Surface Flatness | Poor | Excellent | Excellent |

| Reworkability | Yes/Difficult | Yes/Easy | No |

| Finished Hole Size Uniformity | Poor | Good | Good |

| Good for fine pitch | No | No | Yes |

| Solderability | Good | Good | Good |

| Ideal for HDI products | No | No | Yes |

| Shelf Life | Long | Short | Long |

| Sensitive to Handling | No | Yes | Yes |

| Good for PTH | No | No | Yes |

| Reliability | High | Medium | High |

| Risk of Corrosion | No | Yes | Yes |

| Solder Join Integrity | Excellent | Good | Good |

| Exposed Copper | No | No | Yes |

Price, availability, shelf life, reliability and the assembly process are key factors when selecting a PCB surface finish. While each finish has its own advantages and disadvantages, in most cases, the process, product or environment will dictate the surface finish that is best suited for your application. For example, if your printed circuit boards do not need to be RoHS, Sn/Pb HASL may be your best option. It is low in cost and widely available. If your boards need to be RoHS and have fine pitch components including BGA’s we recommend ENIG or immersion silver.